Description

OFFER FREE INSTALLATION

XINKONG 10,000 LB Capacity L1000 2 Post Car Lift Auto Truck Hoist Open Top

10,000 LBS L1100 OVERHEAD 2 POST LIFT CAR 220V OR 110V

Features: 220V or 110V 60HZ 1PH 3HP MOTOR

Auto Car Lift L 1100

Symmetrical Arm Assembly:

-

- Straight Front / Rear 2 Stage reach from 30 1/4″ to 49 1/5″

- Equal length of front and rear arm design

- Drop-in type lifting pads and truck adapters included

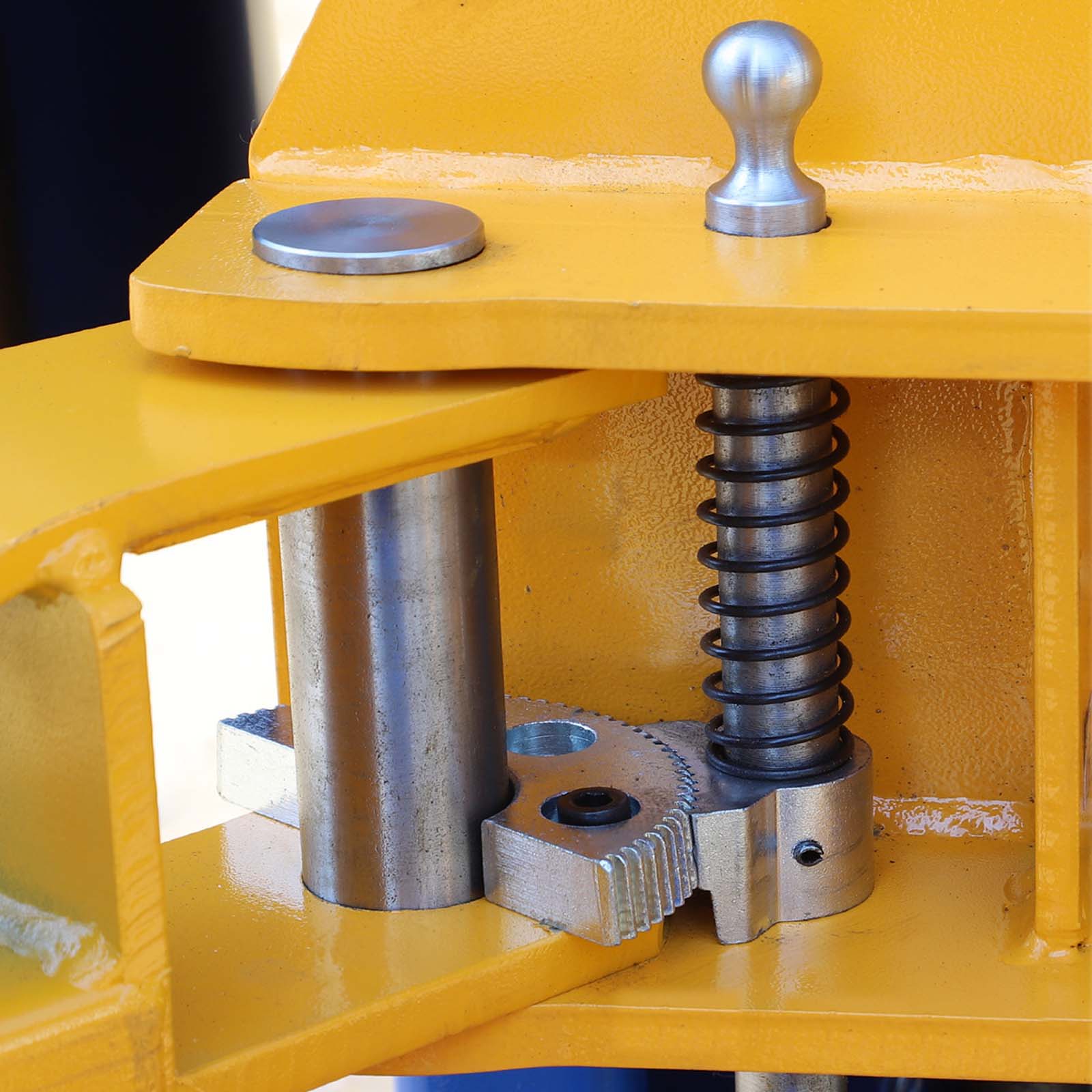

- Safety Mechanism:

- Double Point Safety Lock Release

- Automatic arm lock restraints

- Relief valve built in power pump to prevent overloading

- Door guards protection rubber

- Up-limit switch to protect cylinders working stroke used in safe length scope

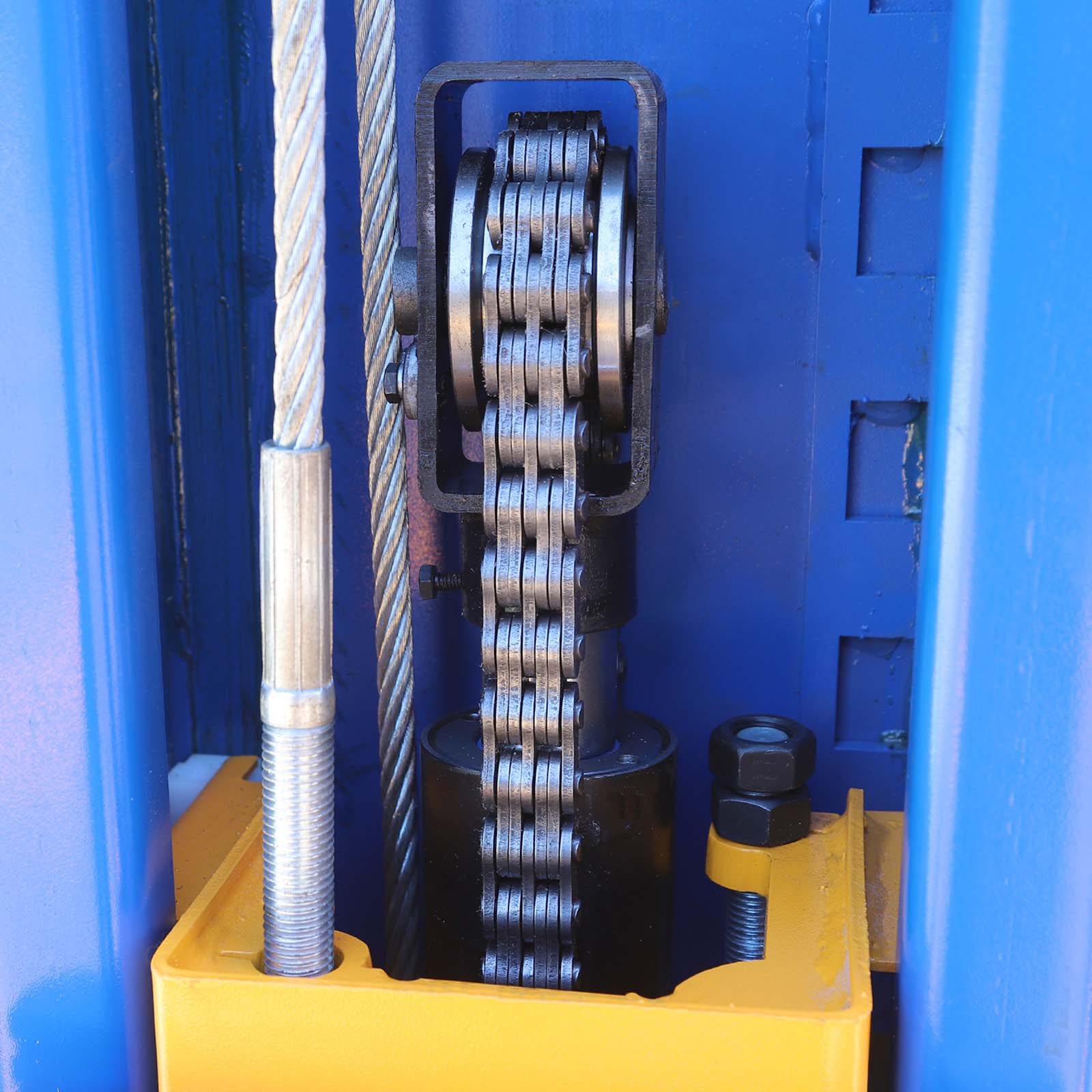

- Heavy duty 5/16″ diameter cable and 4.56″ pulley reduce high stress on

- synchronization process and increase cable life

- Stiffened base plate 5/8″ thickness

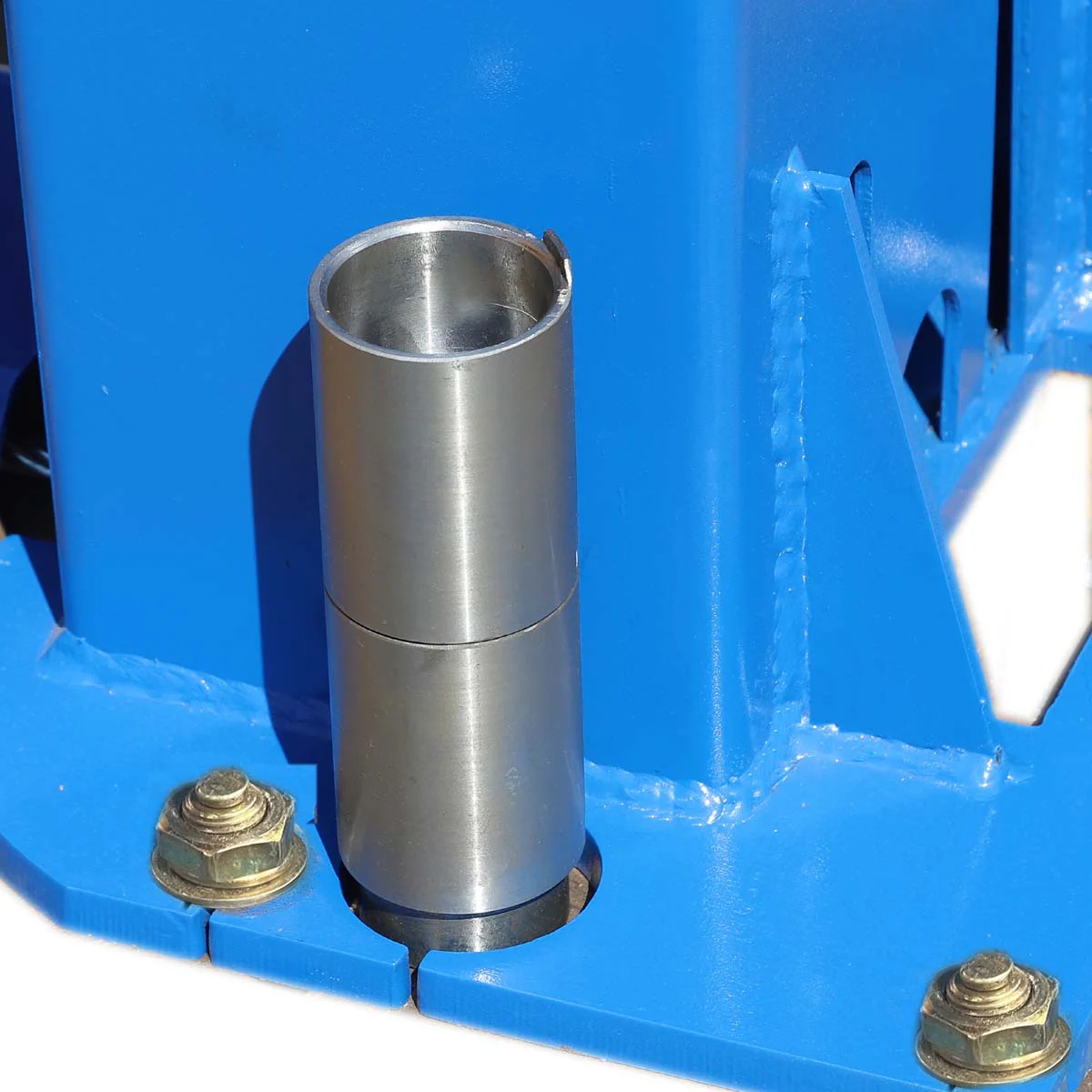

- Ultra high molecular self lubricating nylon slider ensures carriage smooth moving up and down

- Anchor bolts/mounting hardware included

Control System

-

- Lifting operation by pressing “UP” button on motor

- Manual lowering operation by pressing lever

- Relief valve built in power pump to prevent overloading

- 1 sets truck adapters included

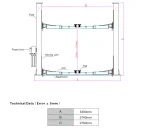

- Lifting Capacity: 10,000 lbs

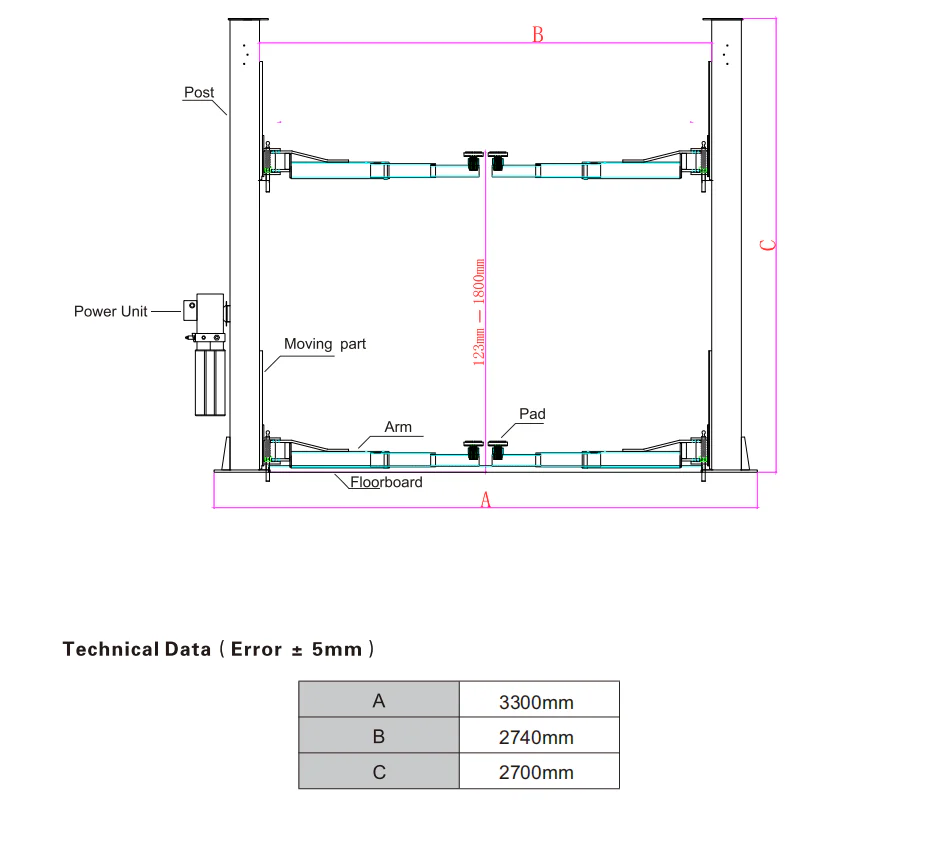

- The overall Height 145-5/8″

- The overall Width 133-1/4″

- Column Width 10.62″

- Base Width 18.89″

- Column Thickness of Steel 3/16″

- Carriage Thickness of Steel 15/64″

- Arms Thickness of Steel 15/64″

- Front Arm 30.7″ to 48″

- Rear Arm 30.7″ to 48″

- Min pad height: 3-7/8″

- Lift height max: 78-7/8″

- Drive-thru width clearance: 100″

- Time to full rise: 20-60 sec

- Shipping Weight: 1460 lbs

Site Selection

Before installing your auto lift, check the following:

Lift Location: Always use architect’s plans when available. Check layout dimension against floor plan requirements making sure adequate space is available. Your lift requires a 220v or 110v, 30amp, single phase, grounded electrical source. There should be room enough to operate the lift in a safe manner and without restrictions.

Overhead Area: The area where the lift will be located should be free of overhead obstructions such as heaters, building supports, electrical lines, doors, lights, etc.

Floor Area: Visually inspect the site where the lift is to be installed and check for cracked or defective concrete.

Floor Requirements

A level floor is suggested for proper installation and level lifting. Small differences in floor slopes may be compensated for by proper shimming. If a floor is of questionable slope, consider a survey of the site and/or the possibility of pouring a new level concrete slab.

New concrete must be adequately cured for at least 30 days.

DO NOT install auto lift on any asphalt surface or any surface other than concrete.

DO NOT install auto lift on expansion seams or on cracked or defective concrete.

DO NOT install auto lift on a second/elevated floor without first consulting building architect.

DO NOT install auto lift outdoors unless special consideration has been made to protect the power unit from inclement weather conditions.

Concrete Specifications

All models MUST be installed on 3,000 PSI reinforced concrete only. Additional concrete requirements will vary by lift.

8,500 lbs – 10,000 lbs lifts: 4″ Minimum Thickness

11,000 lbs – 15,000 lbs lifts: 6″ Minimum Thickness

Shipping:

– We only ship inside the USA 48 States .

Equipment Required for unloading:

– Forklift or Tractor is required from customer for unloading the product.

– Feel Free to ask us any question or concerns. (we will get back to you within the 24 hrs).

– We’ll try our best to reply within 24 hours on working days. (48 hours on weekend or holidays)